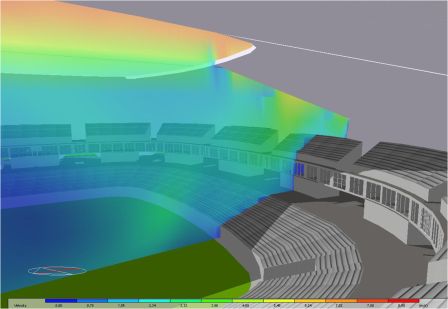

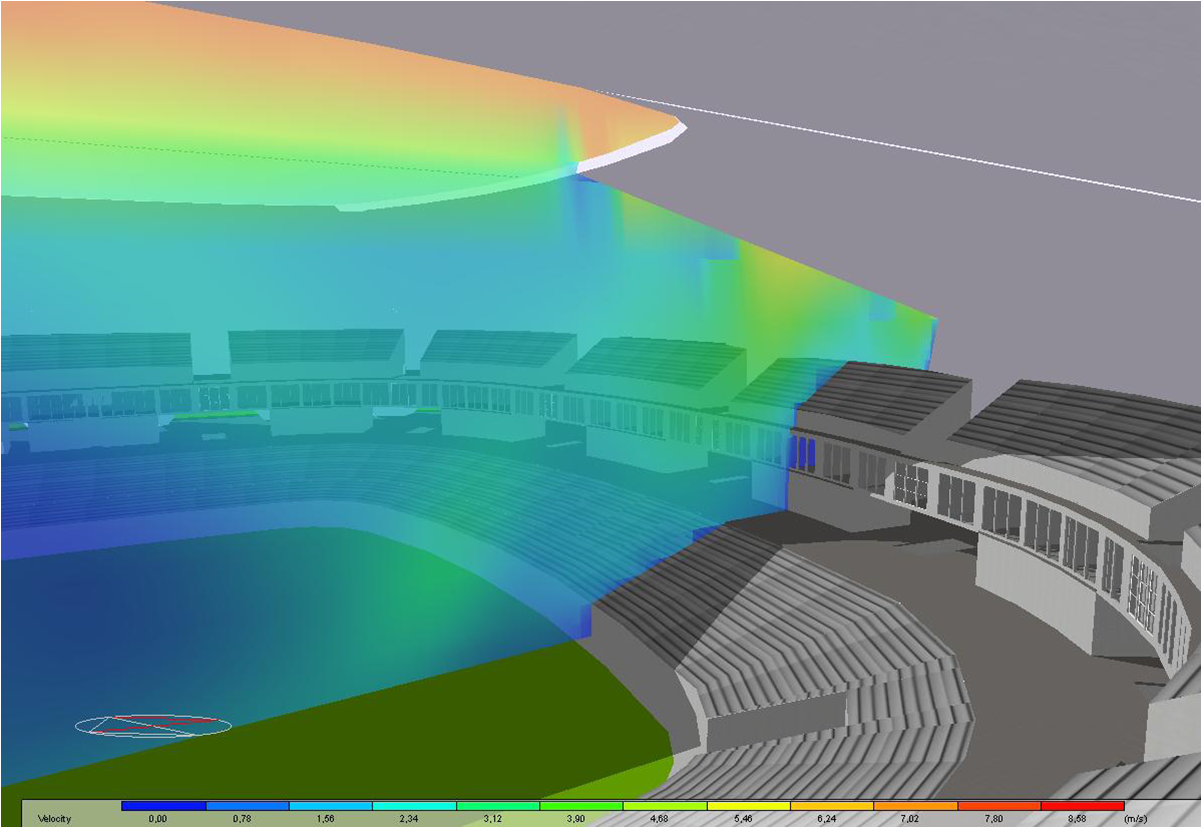

Projekt - Stadion Manaus

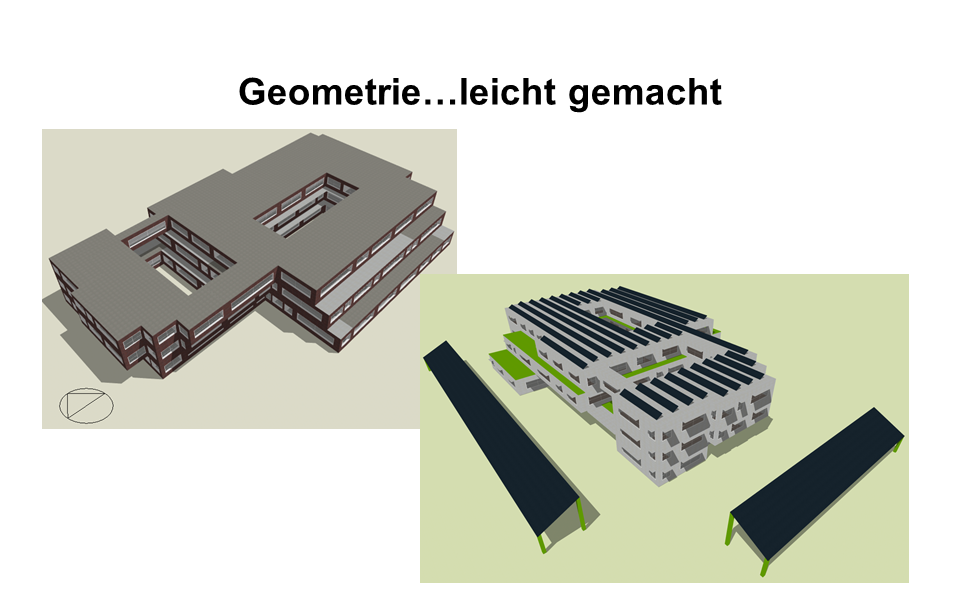

Bei Stadion Manaus ist die gleiche geometrische Model benutzt worden für

- LEED Simulation nach ASHRAE 90.1 (Ganzjährliche Energieeinsparung)

- Natrurliche Belüftungssimulationen für LEED IEQc2 (Beweis für Mindestluftwechsel ohne Behaglichkeit zu gefährdern)

- Übertemperatur Kelvinstunden mit Berücksichtigung von Kondensat ausschaltung von Kühldecken

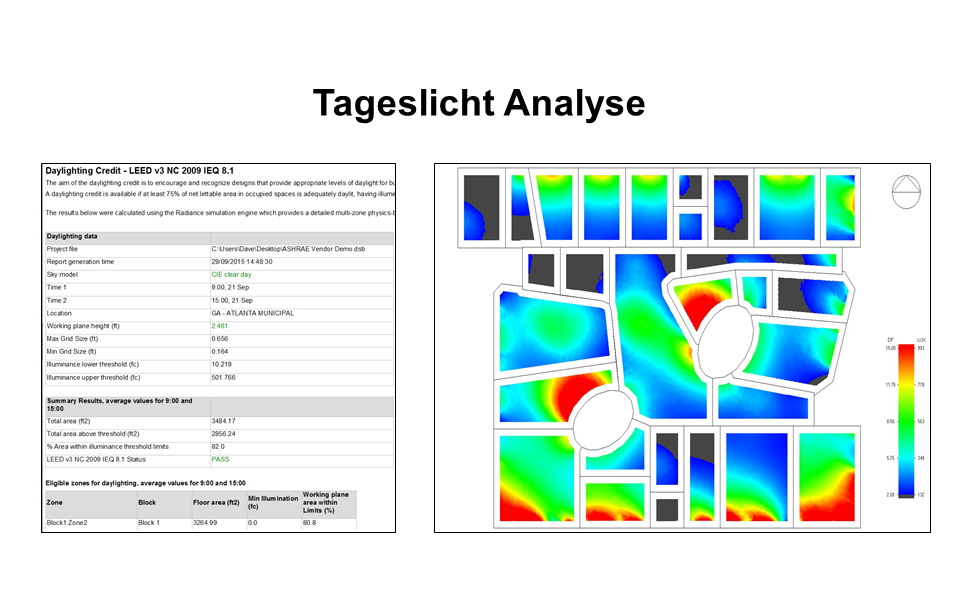

- Tageslichtberechnungen

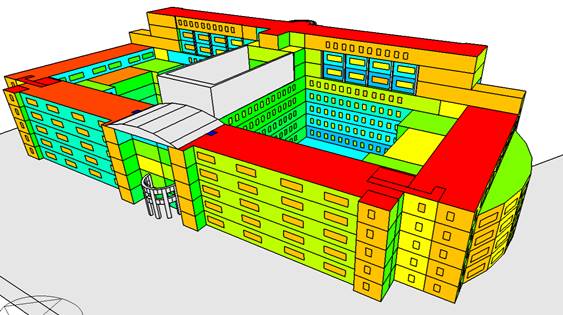

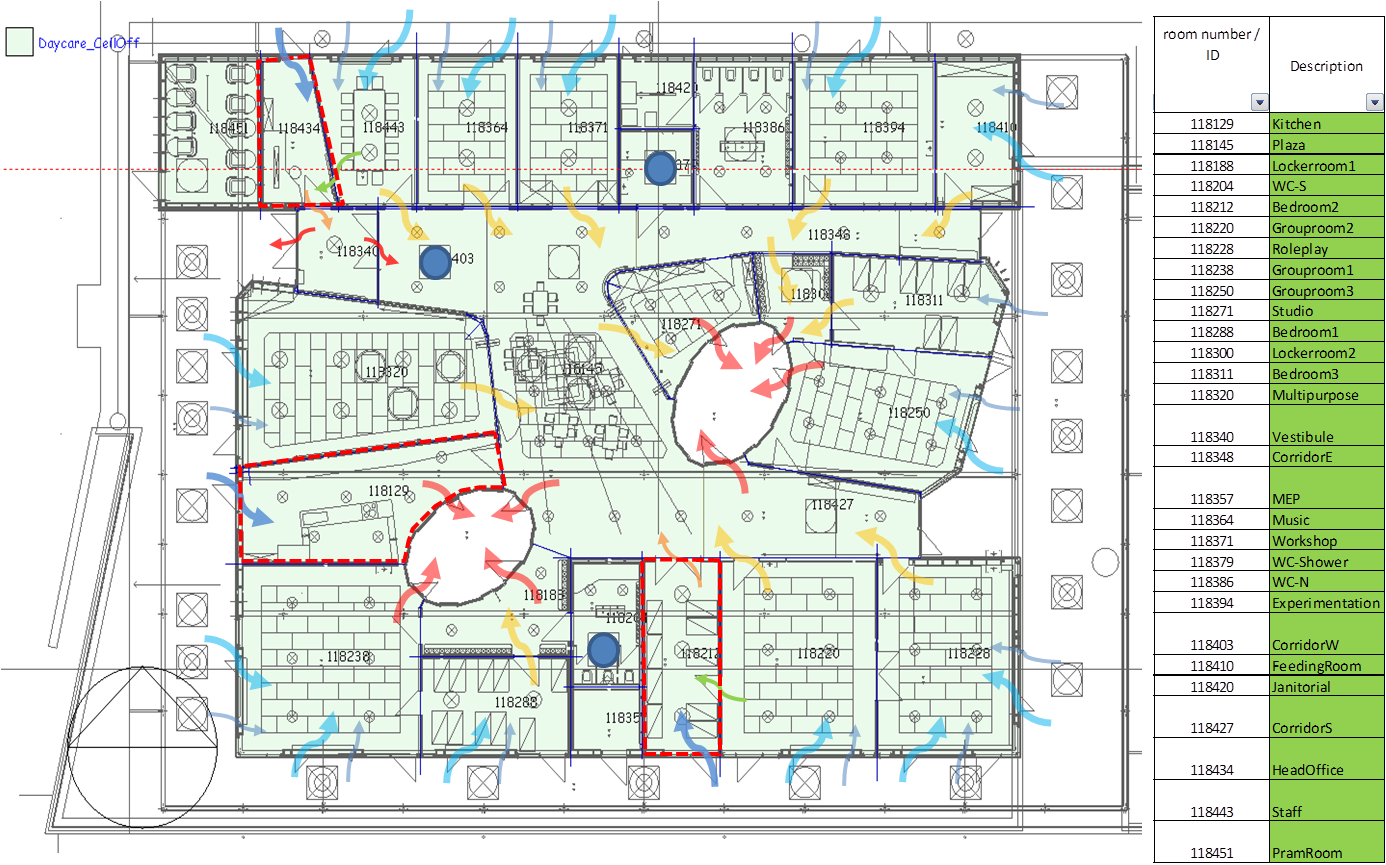

Project Stats - Kita Schloss-Geister

Project type: LEED BD+C: Schools v3

- LEED 2009 Silver, new construction

Location: Karlsruhe, Germany

Building type: Daycare

Floor area / stories / occupancy:

7141 ft² (663 m²) / 1 / ave. 52, max. 86

Budget: Withheld

Project stage: Design Development

Project Description / Features:

The project is built on an existing underground parking facility, featuring

- saves 36% energy costs and 30% water

- mainly timber build and façade with wooden terraces with large canopies

- floor heating

- low energy lighting

- window ventilation as part of a designed natural ventilation concept

- green roof for decreasing peak storm water run-off and reducing heat-island effects

- water saving perlators on low flow faucets, scald protection on hot water faucets

- duel flush toilets

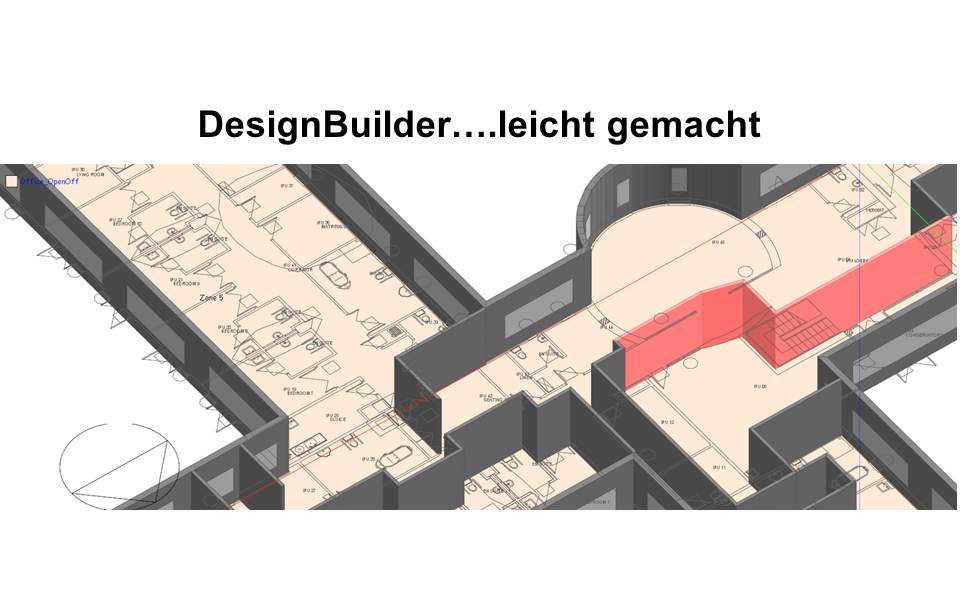

- skylights and partition windows to promote use of daylight

- glazed internal courtyards to promote use of daylight

- no permanent irrigation

Challenges / Questions

The following had to be quantified using simulation

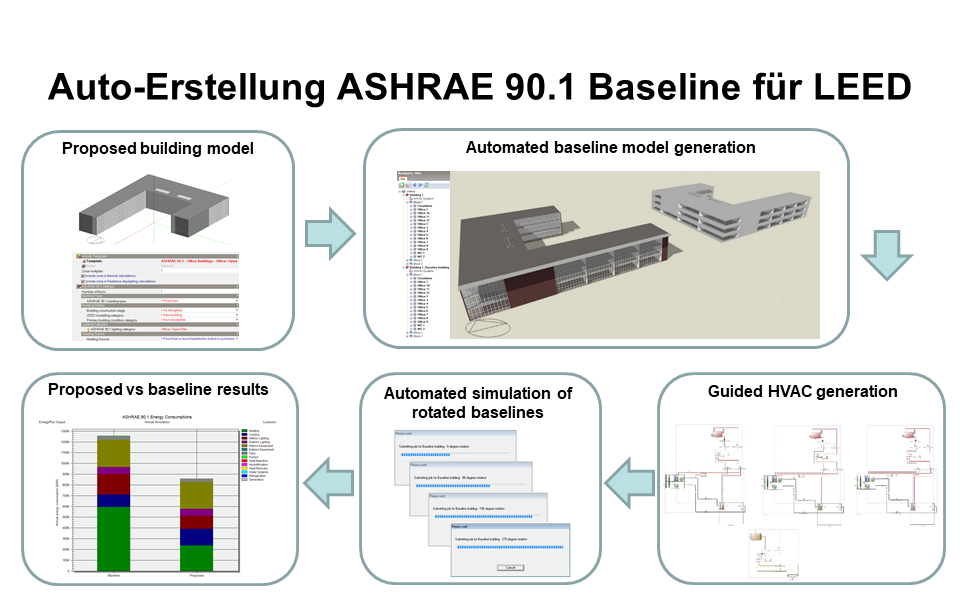

- energy cost savings as per ASHRAE 90.1 PRM for LEED

- daylighting effectiveness

- prove natural ventilation is an effective strategy that would increase occupant comfort

Solutions / Answers

The first part was supposed to be easy…it wasn’t...because it was window-ventilated.

New builds of today’s “style” provide very air tight, highly insulated structures. When new builds don’t have mechanical ventilation and are not occupied at night, the structure has no way to release heat. To make matters worse the current architectural trends use more glazing than they should. The result is that many window-ventilated new builds overheating for many, many hours during the year.

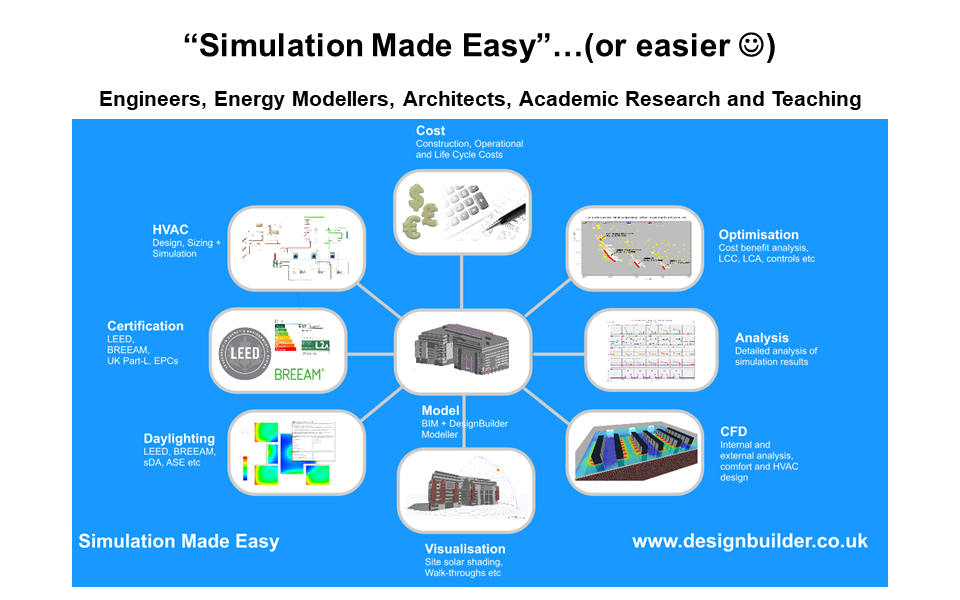

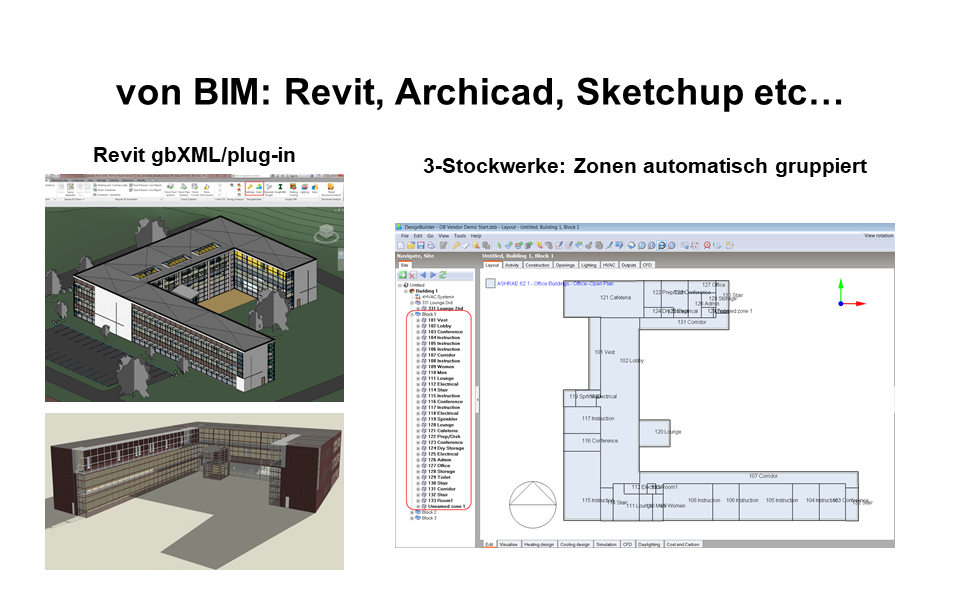

To be consistent across LEED credits, it made sense to use one model to cover all 3 points. DesignBuilder does this perfectly. What’s more, it was as easy as pressing on a button to set up the very complex air flow network for the natural ventilation simulation. The same goes for the daylighting simulation (which was very fast and helpful during the schematic design phase).

The difficulty was in handling the human driven window ventilation within the bounds of ASHRAE 90.1. As soon as you open a window in winter, the heated floor heating system will not meet setpoint resulting in unmet load hours which may not exceed 300. Also, the baseline building must have the same 0 cfm (m³/h) mechanical outdoor air rates whilst keeping the infiltration and window ventilation the same as that of the design case model even though it uses different glazing sizes!

Furthermore, the discomfort that occurs during short periods of opening a window or overheating had to be quantified and included norm defined definitions of discomfort due to thermal (temperature, humidity, airspeed), draft and CO2 to prove the 3rd point.

The project dealt with this by having auxiliary (small) venting windows that only open 4 inches (10 cm), so as not to over ventilate, whilst the large windows could fully open mainly for cooling. Motorized shading was included on the south façade (also human driven and manually controlled).

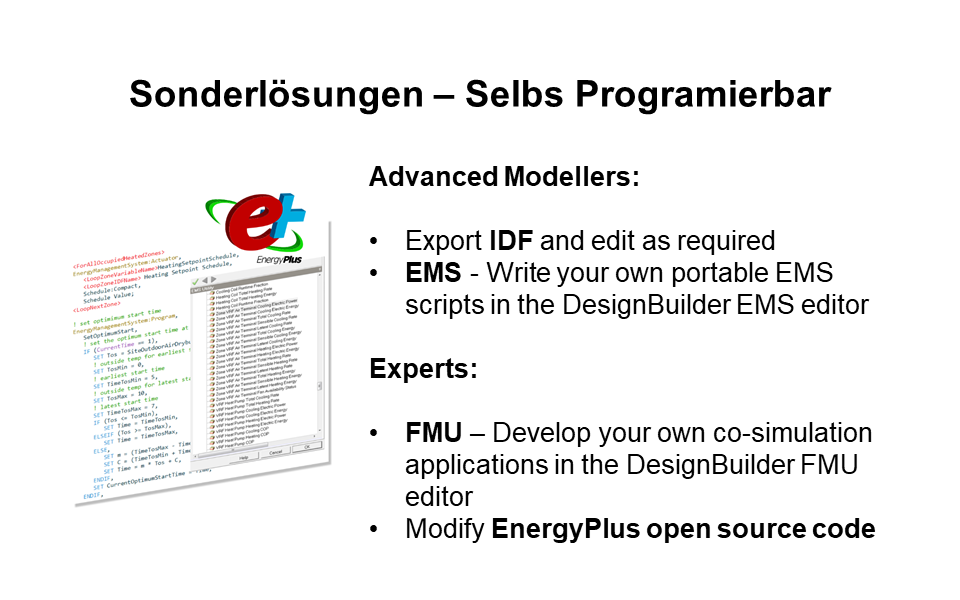

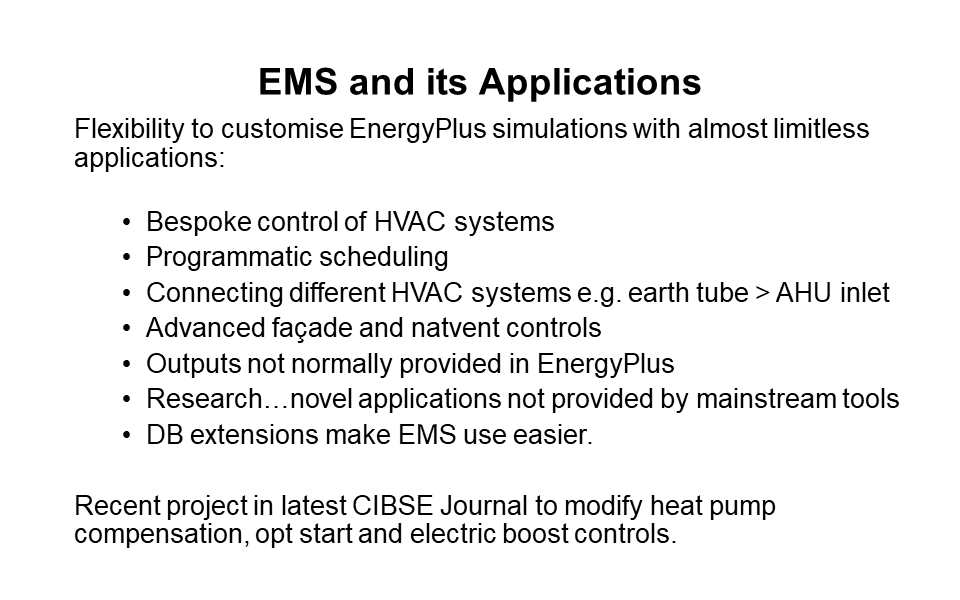

On the modeling side, the human driven control of windows based on comfort, was an exceptionally high effort in terms of EMS (custom logic) (which is now possible within DesignBuilder) and resulted in a paper WINDOW SIMULATION METHODS REQUIRED FOR MANUAL WINDOW VENTILATED BUILDINGS and the new object incorporated as of EnergyPlus v8.3 called the AirlowNetwork:OccupantVentilationControl object. EMS was also used to drive the shading and lights in a similar manner. Seasonal tree transmittance was modeled.

Projekt - Ballet am Rhein

PPP-Verfahren gmp ∙ Architekten von Gerkan, Marg und Partner

mit HOCHTIEF Solutions AG und HMI, BIG und Capatti Staubach

Entwurf Volkwin Marg und Hubert Nienhoff mit Kristian Spencker

Mitarbeiter Veit Lieneweg, Silvia Schneider, Michael Scholz, Ramona Schwertfeger, Elisa Rodriguez,

Elke Glass, Katerine Witte, Daniel Tome

Bauherr Landeshauptstadt Düsseldorf

BGF 4.500 m²

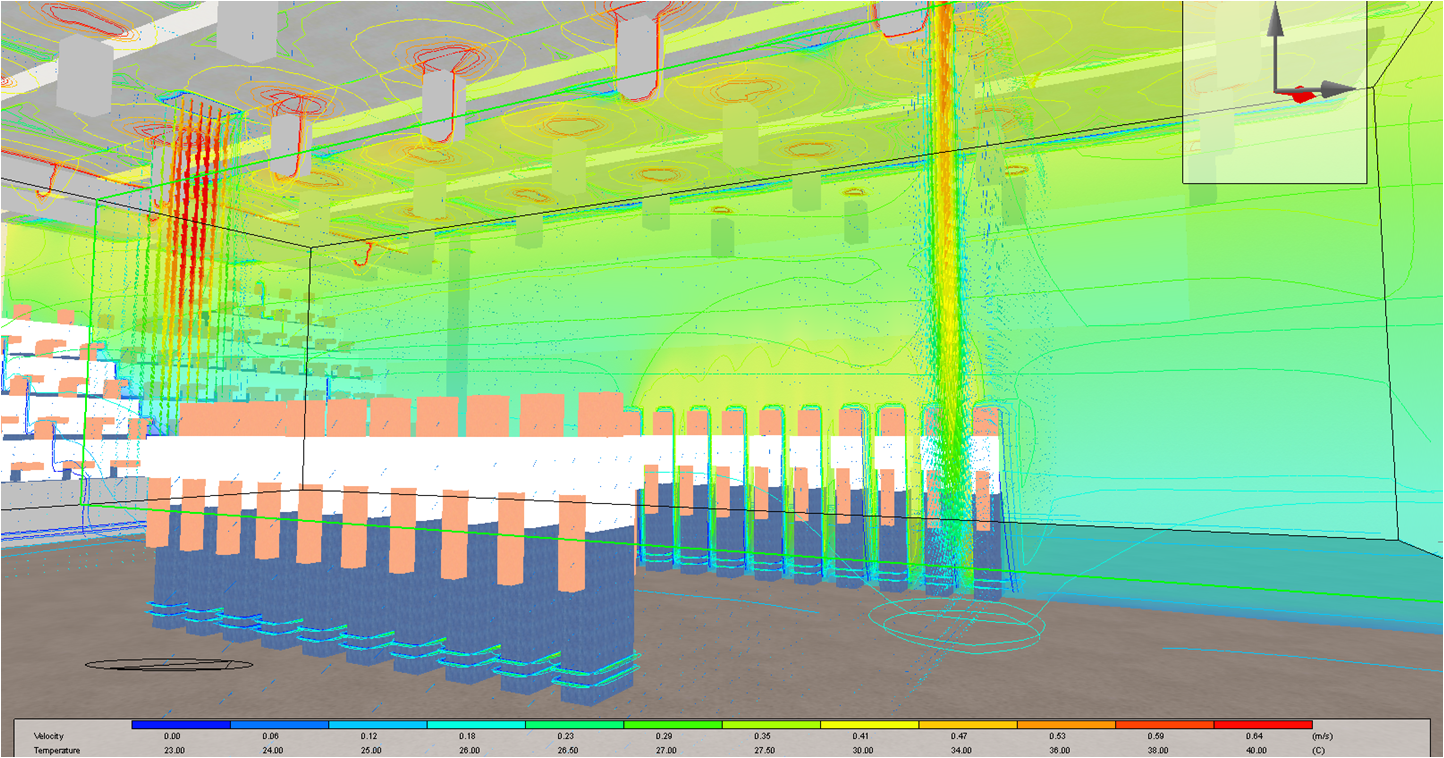

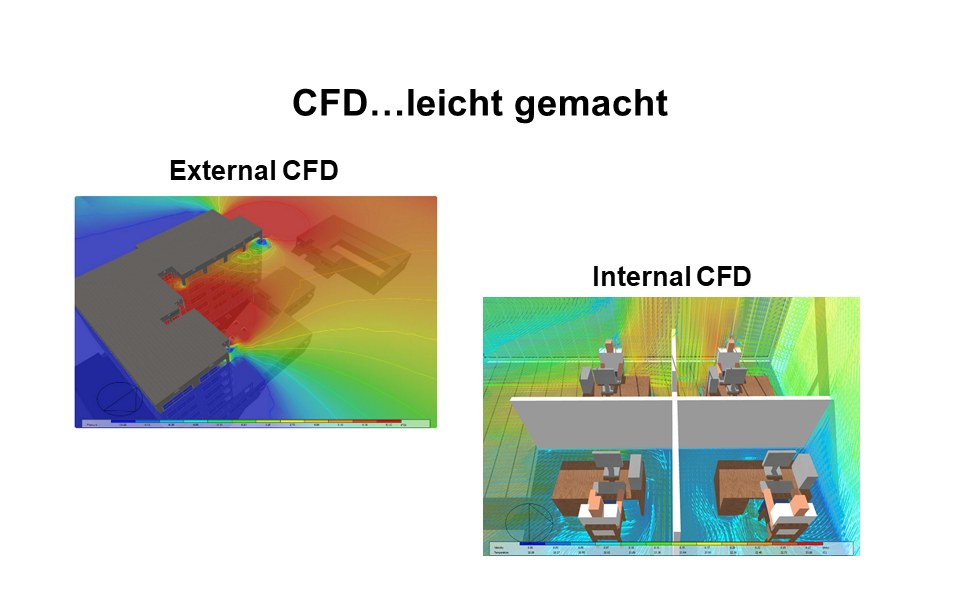

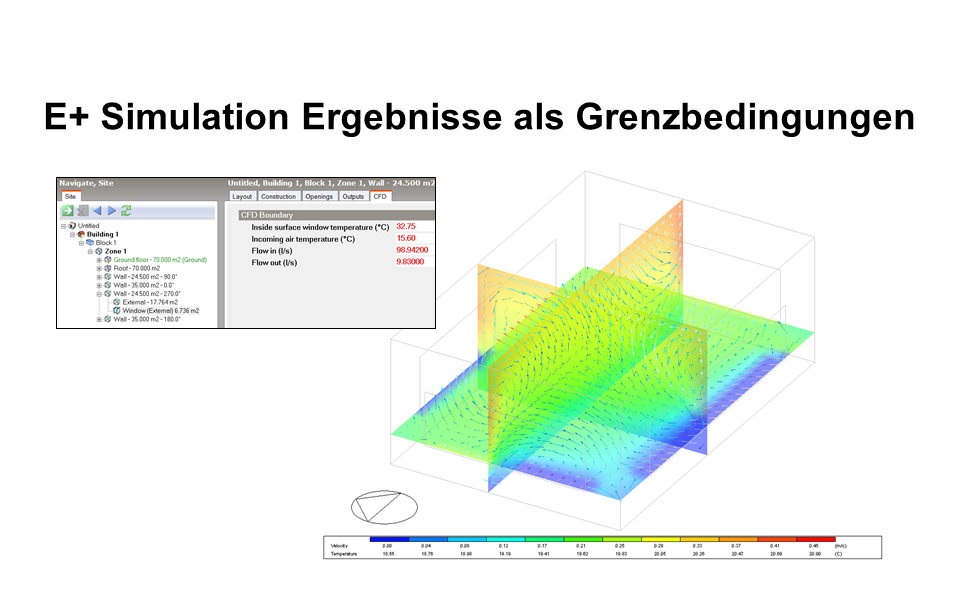

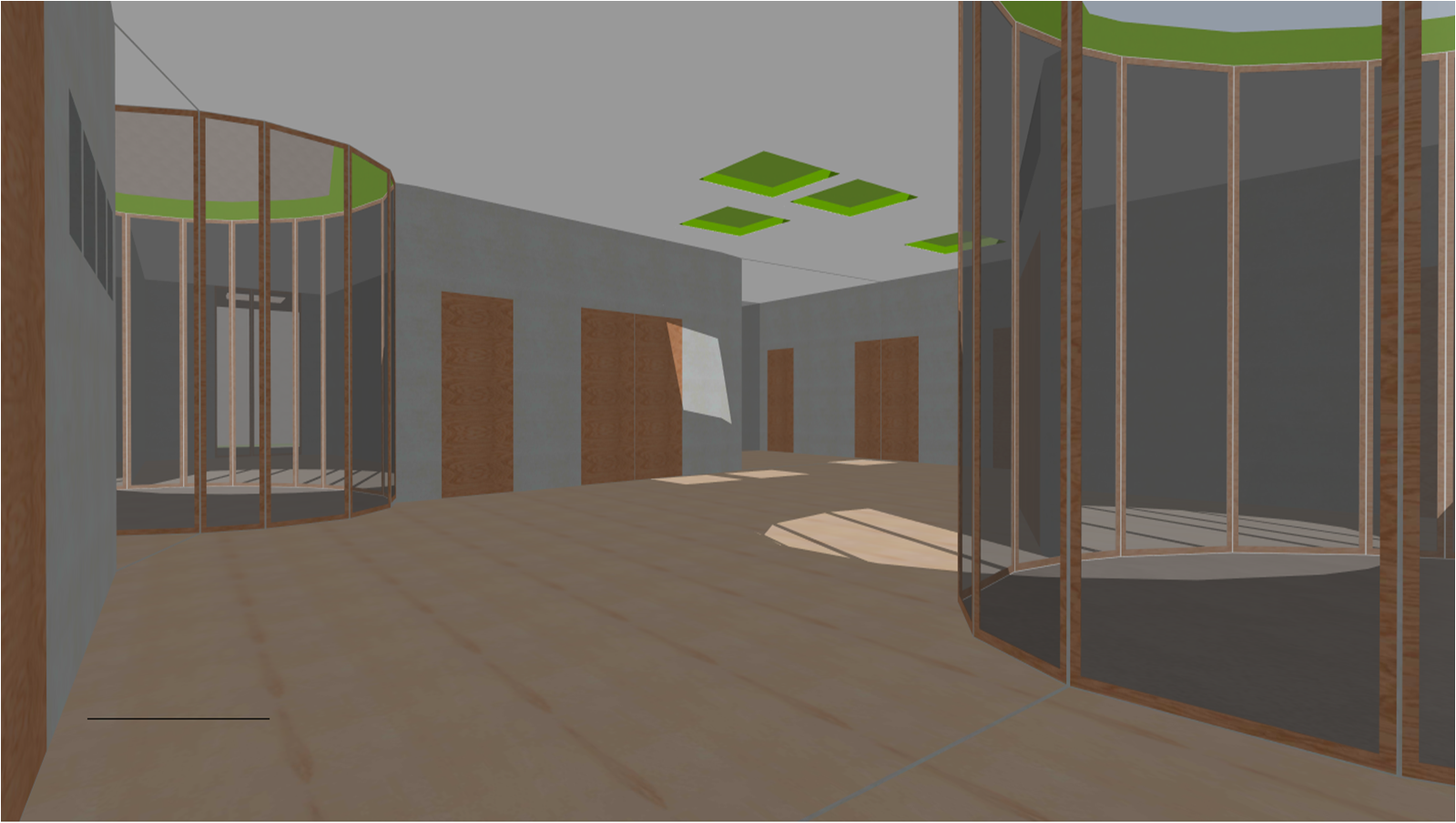

Sicherheid bei der Planung - Theater CFD

Die Kombination von Verdrängungsauslässen unter den Ständern als Verdrängungslüftung mit Verdrängungsauslässen in den Kühldecken würde eine Komfortanalyse unter Verwendung von CFD-Simulationen erfordern. Dadurch wurden Positionen und Temperaturen optimiert.